About US

Snell Prosthetics & Orthotics has always been an early adopter of new technology and has participated in beta testing for several new devices and components for manufacturers. It is the mission of Snell Prosthetics & Orthotics to provide the most appropriate level of technology for each of our patients and deliver outstanding customer service to all.

WHERE CARING MOVES

We continually strive to restore the highest level of mobility and function possible to our patients, with devices that not only meet the individual’s needs, but that are also pleasing in appearance.

We recognize that the best patient care takes place when the rehabilitation protocol is team oriented-consisting of the patient, family, physician and other healthcare professionals, in addition to our certified and licensed professional staff.

OUR TEAM

SERVICE WITH A SMILE

WHO WE ARE

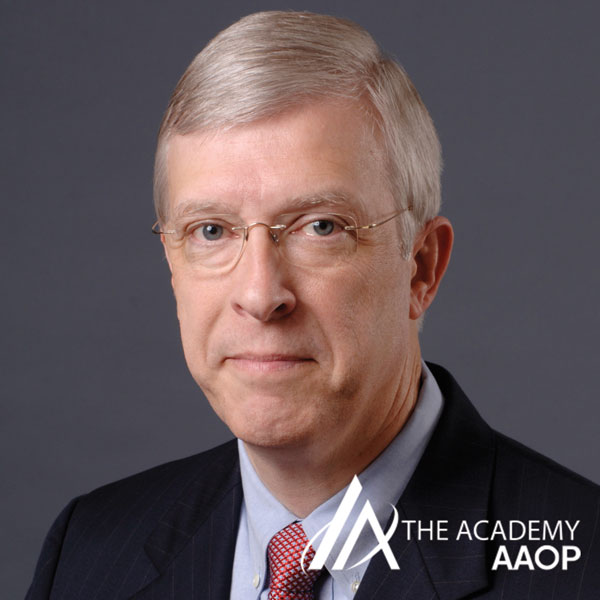

FRANK SNELL, CPO, LPO, FAAOP - PRESIDENT / CHIEF EXECUTIVE OFFICER

A certified prosthetist and orthotist for more than 50 years, Frank Snell has served over 200,000 patients and fitted over 18,000 prostheses. Throughout his professional career, Frank Snell has completed more than 60 advanced professional courses to earn certification or achieve manufacturer-directed competency on an impressive array of prostheses, orthoses, and components.

On a local level, he has continuously served as a prosthetic consultant to the Veterans Administration Prosthetic Amputee Clinic (currently held at the Eugene J. Towbin Healthcare Center in North Little Rock) since 1972.

On a national level, when injured soldiers with significant limb loss began returning from conflicts in Afghanistan and Iraq, the Department of Defense (DoD) sought out some of the country’s most respected prosthetists to provide knowledge on how to best treat them. Frank Snell was one of only a dozen prosthetic consultants selected nationwide to participate in the DoD’s Microprocessor Knee Forum. The goal of this forum was to develop new prostheses that would give service-member amputees more flexibility and help them better perform their military jobs should they choose to continue active duty.

Frank Snell, CPO, LPO, FAAOP was one of the first ten practitioners in the country to earn the signature designation of Fellow of the American Academy of Orthotists & Prosthetists (FAAOP). This elite status is only attained by those with a demonstrated commitment to mastering their profession through sustained educational pursuits and a proven track record of service to both their community and the O&P profession.

Since 2008, Frank Snell has been instructing physical medicine residents as an adjunct clinical assistant professor at the University of Arkansas for Medical Sciences. He also routinely serves as a guest lecturer for the University of Central Arkansas’ Occupational Therapy Program, Harding University’s Physical Therapy Program, and Baptist Health College’s Occupational Therapy Assistant’s Program.

Investing In The Future

Since 2008, Frank Snell has been heavily involved in education, serving as an adjunct clinical assistant professor to physical medicine residents at the University of Arkansas for Medical Sciences (UAMS). He also routinely serves as a guest lecturer for the University of Central Arkansas’ Occupational Therapy Program, Harding University’s Physical Therapy Program, and the Occupational Therapy Assistant Program at Baptist Health College.

WHERE CARING GIVES

CONTINUOUS EFFORTS TO IMPROVE PATIENT CARE

At Snell Prosthetics & Orthotics, we believe that patient care is a continuous service and our efforts to improve patient care extend well outside the walls of the clinic. From local charity events to policy forums in Washington D.C., we are always looking for ways to advance the care for those we serve on both a local and national scale. Through an abundance of volunteer hours and philanthropic service, we use our “where caring gives” mindset to further support our patients and partner organizations.

WHERE CARING started

FOUR GENERATIONS OF EXCELLENCE

When R. W. “Pop” Snell began his company, Snell’s Limbs and Braces, back in 1911, there were no rules or precedents to guide him as he first began handcrafting each custom-fitted artificial limb. The only guideline he utilized was his own belief that an important need required him to begin a generations-long voyage of discovery in a continuing search for better and better solutions.

With no established norm to follow, Snell set his own style, responding proactively and creatively. From those early limbs fashioned of rawhide and red willow, through the following war years and the wave of returning disabled veterans in need of his services, the business prospered.

It was a business to which the family remained committed. From the beginning, the Snells created the benchmark for quality and service in the fields of prosthetics and orthotics.

When the first standards tests were established in 1948, Ed Snell was among the first wave of practitioners to qualify as a Certified Prosthetist and Orthotist (CPO).The company also strongly supported the Veterans’ Administration’s earliest efforts to encourage progress and development by testing new components and designs, and assessing and reporting the results of research conducted in Snell’s own laboratory.

Current Snell’s president Frank Snell, CPO, FAAOP, a great-nephew of the original founder, began working alongside his father at the rapidly-growing company as early as age 14, developing the skills required for an Orthotist/Prosthetist. When he joined the company full-time in 1972 as a graduate of Northwestern University, he brought with him new marketing and management skills and methods as well as new insights and goals.

His improvements included changing the company’s name in 1976—to the current Snell Prosthetics & Orthotics. By the time Ed Snell retired and his son assumed the company presidency in 1984, more changes were under way. Foreseeing the coming climate of empowerment for the disabled as reflected in such legislation as the Americans with Disabilities Act, Frank Snell oversaw the construction of the current Little Rock office at 625 North University Avenue, rapidly followed by the opening of satellite offices across the state. In addition, Frank quickly determined that CAD/CAM technology was worth investing in and thus became the first independent prosthetics and orthotics facility in Arkansas to implement computer aided design and manufacturing in the late 1980’s.

Today, she is the vice president of Business Development for the practice. As well, son Brant Snell, Chief Operations Officer, upholds the family tradition joining the company in 1997.

Snell has witnessed amazing progress in the field of prosthetics since Pop Snell originally fit the company’s first patients with wood and rawhide prosthetic limbs. The decades since have brought many improvements through the use of lighter-weight thermosetting resins with their superior strength and durability, while more modern developments have relied on the use of materials such as acrylics, thermoplastics and epoxy resins. Today’s hi-tech componentry and microprocessor technologies continue to greatly improve the devices that Snell fabricates.

Orthotics, too, has made dramatic strides during Snell’s over 100-year history. The heavy metal support braces and orthoses once used to benefit polio survivors and patients with muscular weaknesses have metamorphosed into today’s light, strong plastics. The leather used for orthotics originally had to be hand-cut, water-soaked, shaped and adjusted with a hammer over a 10- to 14-day period. Today’s NASA-inspired plastic orthoses are shaped by wrapping them around heat-molded therma-cork materials, in a process that takes less than two days. In 2006, Snell became one of the first independent facilities in the nation to undergo training in myo-orthotics technology, with the Walk-Aide device. Today, the practice is one of the leaders in the country in applying this myo-orthotic device, when appropriate.

Thanks to our shared concern for quality and determined pursuit of the best ways and means to serve our patients, today our capabilities offer an amazing variety of possibilities which enable the disabled to lead more active, mobile, and independent lives.